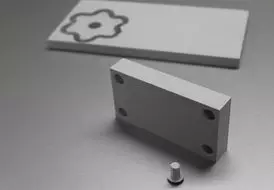

POM, PET, and their variations are among the most widely used plastics, offering versatile design options. These materials are highly machinable and provide excellent dimensional stability.

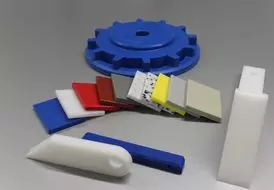

PLASTIC PRODUCT PORTFOLIO

HIGH PERFORMANCE PLASTICS (POM, PET)

POLYAMIDES (PA)

Polyamides (PA) are a group of synthetic polymers known for their strength, durability, and resistance to wear and chemicals. They are commonly used in a wide range of applications, including in automotive, textiles, and engineering components, due to their excellent mechanical properties and dimensional stability.

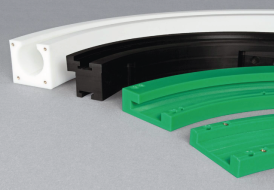

POLYETHYLENE (PE HD 300, PE HMW 500, PE UHMW 1000)

Polyethylenes are widely used in applications that demand excellent lubricity, high wear resistance, and long-lasting durability. These materials are ideal for situations where low friction and the ability to withstand frequent wear and tear are essential, making them suitable for a variety of industries, including manufacturing, automotive, and machinery.

ENGINEERING PLASTICS (PP,PVC, PTFE AND OTHERS)

PP (polypropylene) and PVC are commonly used materials in industries like manufacturing, construction, and chemicals. They are ideal for producing tanks, septic systems, pits, pools, and similar applications due to their durability, chemical resistance, and reliability.

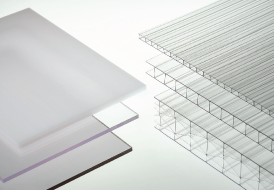

CLEAR PLASTICS (PC, PET-G, PMMA)

Clear plastics are transparent materials that allow light to pass through, making them ideal for applications where visibility or optical clarity is important. These plastics are commonly used in industries such as packaging, automotive, and electronics. Examples of clear plastics include acrylic (PMMA), polycarbonate (PC), and PET, which offer high transparency, impact resistance, and ease of processing, making them suitable for a wide range of products like windows, lenses, displays, and protective covers.

PLASTIC FLOORS (PP, PVC, PE)

Plastic puzzle floors are interlocking tiles made from durable materials like PP, PVC, designed for easy installation and cushioning. Commonly used in gyms, garages, play areas, and workshops, they offer comfort, shock absorption, and durability, while being simple to assemble and maintain.

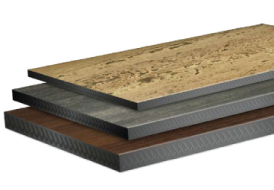

HPL FACADE SHEETS XCL

HPL (High Pressure Laminate Board) Crown XCL is produced in a thermoset press at high temperatures and pressures; additional double-reinforced acrylic PUR resins ensure the long lifespan of the panels. With its high density and strength, CrownXCL offers excellent dimensional stability and resistance to weathering, UV radiation, impacts, and scratching.

PLASTICSUPPLIERS.CO.UK

AWESOME FACTS

PRODUCTION PORTFOLIO SHOWCASE

We specialize in custom plastic production for a variety of industrial applications, offering durable and high-quality solutions. Our custom plastic products include water tanks made from UV-resistant and corrosion-resistant materials like polyethylene and polypropylene, perfect for both potable and non-potable water storage. We also produce chemical tubs designed to safely store hazardous materials, featuring excellent resistance to harsh substances and custom options like reinforced walls and drainage systems. Additionally, we create components for waste air purification systems, such as gas scrubbers and droplet separators, using high-resistance thermoplastics to handle corrosive gases and meet environmental standards. For technical and engine rooms, we provide robust plastic solutions, including tanks, ventilation systems, and protective enclosures, built to withstand extreme conditions and ensure smooth operation. If you haven’t found exactly what you’re looking for, don’t hesitate to contact us. Our team is ready to collaborate with you on custom solutions tailored to your specific needs.

CUSTOM TANKS

WASTE AIR FILTERS

INDUSTRY TUBS

ANIMAL BOXES

DOSING SYSTEMS AND EQUIPMENT

AIR SYSTEMS MADE FROM PLASTIC

CUSTOM TECHNICAL ROOMS AND ENGINE ROOMS

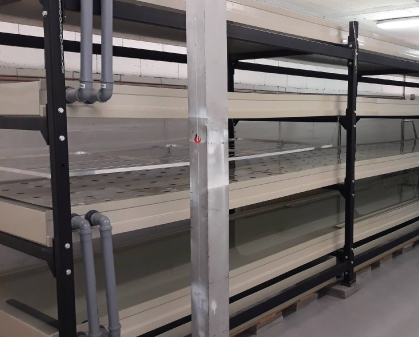

AQUAPONICS & HYDROPONICS SYSTEMS

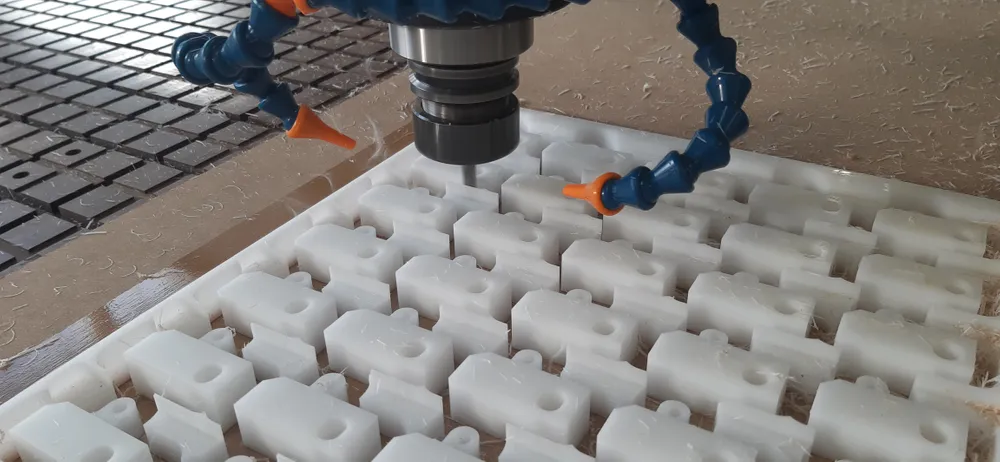

MACHINING OF THE COMPLETE RANGE