In addition to our custom plastic products, we also offer CNC milling, bending, and cutting services to precisely shape and fabricate plastic materials according to your specifications. If you haven’t found exactly what you’re looking for, don’t hesitate to contact us. Our team is ready to collaborate with you on custom solutions tailored to your specific needs.

SERVICES

PLASTIC BENDING

For bending plastic sheets, we use the PWO 2000 machine, designed for bending materials such as PE, PP, PVC, PMMA, and ABS. The machine consists of two interconnected tables, which can be separated when needed. One table serves as the heating table, while the other is the bending table. The lifting of the heating strip and the clamping of the bending jaw are both operated by pneumatic cylinders.

- The bending machine is designed to meet both standard and more demanding requirements, such as the production of exhaust ducts for ventilation and technological systems.

Maximum working width: 2000 mm

Material thickness: 2 – 15 mm

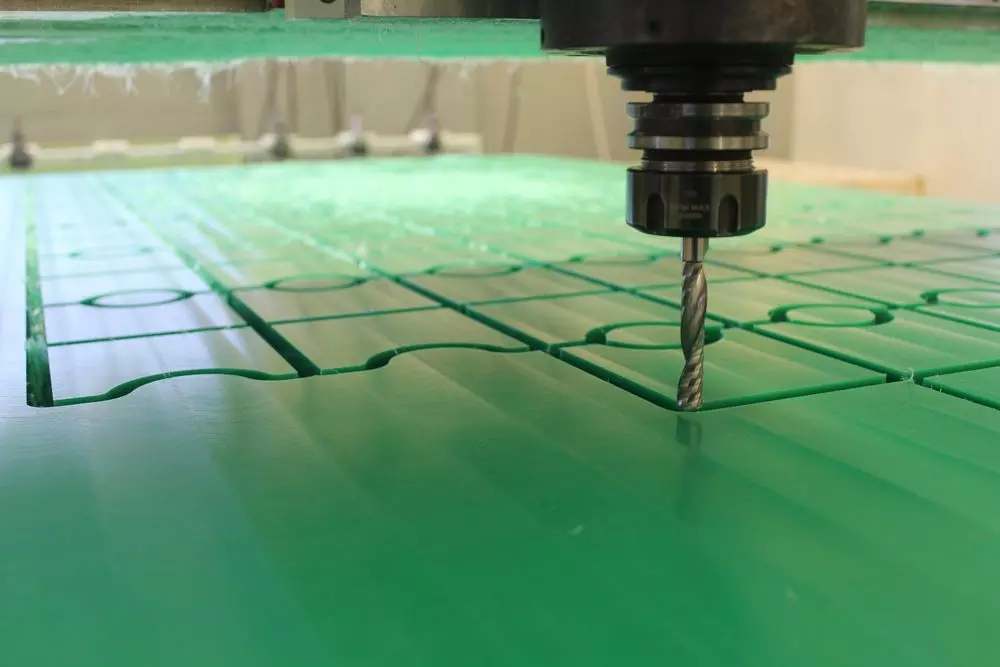

CNC MILLING & CNC TURNING

Our milling machines feature worktable dimensions of 3090×2030 mm and 5000×2050 mm, allowing them to cut large sheet materials. They enable machining of a wide range of sheet materials, including:

- Technical plastics (PA6, POM, PE-HD, PE500, PE1000, etc.)

- Acrylic (PMMA / plexiglass)

- Polycarbonate (hollow, solid)

- Composite panels (aluminum sandwich materials like Dibond, Alucobond, etc.)

- PVC

- HPL panels (high-pressure laminates like Fundermax, Crown, etc.)

LASER CUTTING

We offer high-precision laser cutting services, ideal for a variety of materials, including plastics, acrylic, polycarbonate, and more. Laser cutting provides clean, accurate cuts with minimal material distortion, making it perfect for intricate designs and detailed components. This technology allows for tight tolerances and smooth edges, ensuring high-quality results for both small and large production runs. Whether you need custom shapes, complex patterns, or high-volume cutting, our laser cutting services are tailored to meet your specific requirements, offering fast turnaround times and exceptional accuracy for industries such as manufacturing, signage, and more.

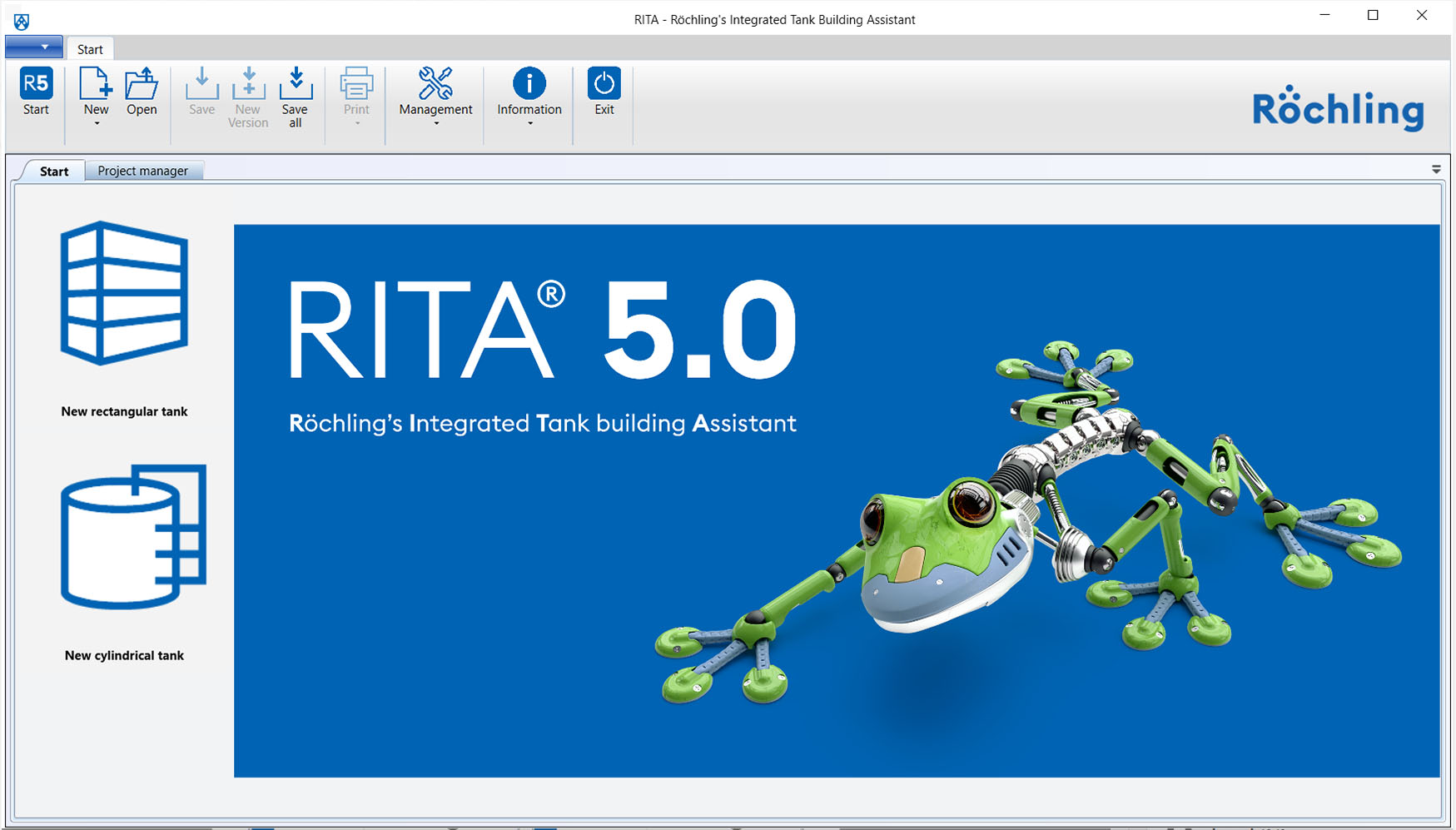

STATICS CALCULATION OF FREE-STANDING ABOVEGROUND TANKS

For the static calculation of free-standing above-ground tanks, we use the RITA® 5.0 software from Röchling. The latest version of this program for calculating tanks, basins, and reservoirs combines proven advantages and 20 years of operational experience with a range of new, useful features.

We are capable of calculating the static requirements for both circular and rectangular tanks. For circular tanks, the software allows for the assessment of the shell structure according to DVS 2205-2 in areas subject to wind and snow loads, as well as the calculation of tank installation in earthquake zones. For rectangular tanks, the program automatically selects and optimizes reinforcement and steel profiles used in the construction.

AUTOMATIC CNC BUTT WELDING MACHINE WORK SP 4000

We are equipped with the WORK SP 4000 CNC welding machine. The entire welding process is controlled by a processor and runs in an automatic cycle. The machine enables welding of homogeneous thermoplastic sheets ranging from 3 to 40 mm thick, as well as welding of sandwich panels up to 80 mm thick. The welding length can reach up to 4200 mm. The design of the machine allows for welding both flat surfaces and cylindrical tank shells. The quality of welding on this machine is significantly higher than with hot gas or extruder welding.

- Pool bottoms welding

- Welding of sheets and flat surfaces

- Manufacturing of hoops and shells

- Welding of sandwich panels and wall elements

These capabilities allow us to provide highly specialized and precise welding services tailored to various applications, ensuring excellent quality and durability of the welded components.