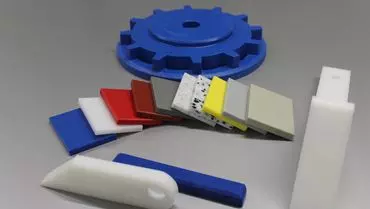

PE – polyethylene semifinished products belong to the group of basic engineering thermoplastics. Depending on the manufacturing process, polyethylene is divided into different types, which vary in their properties and areas of optimal use. PE is the most produced and widely used plastic. This lightweight yet robust plastic is characterized by excellent resistance to chemicals, water, and mechanical wear, making it an ideal material for a wide range of applications. Due to its minimal moisture absorption and ability to withstand extreme temperatures, polyethylene is used in projects ranging from sports equipment to complex industrial components.

POLYETHYLENE PE-HD300, PE-HMW 500, PE-UHMW 1000

PE-HD PE300

High-density polyethylene (PE-HD, PE 300) is a versatile material widely used in industrial applications. Due to its excellent chemical resistance, it is ideal for the production of technological equipment and tanks in the chemical industry. PE-HD is also used in the construction of sports barriers, such as those for hockey and floorball. In its black version, the material is UV stabilized, making it suitable for outdoor applications. This polyethylene also offers excellent electrical insulating properties and is non-toxic, making it ideal for applications in contact with food.

PE 500 - PE HMW

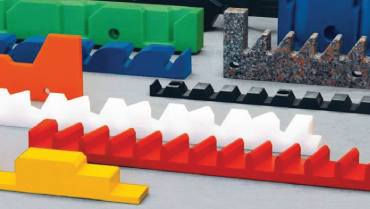

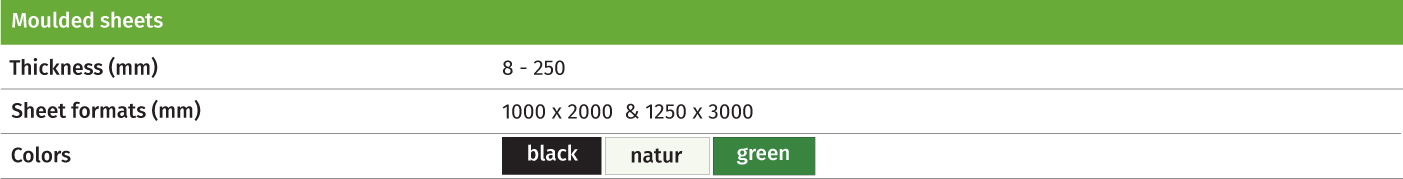

Better abrasion resistance and good sliding properties compared to PE 300, together with higher resistance to sub-zero temperatures freezing temperatures. Other properties are comparable to PE 300. PE-500 is mainly used in the production of instruments, machinery and equipment wherever increased strength is required when exposed to chemicals at low temperatures. The material is suitable for the food industry as table tops, demolition boards and wall linings. We supply it in more colour versions for many applications, also for the engineering industry, chemical industry and sports venues.

PE 1000 - PE UHMW

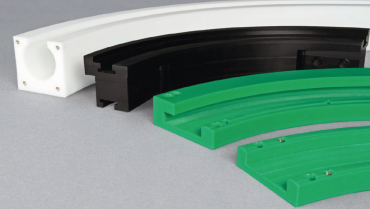

Polyethylene PE 1000, also known as PE UHMW (Ultra High Molecular Weight), is a high-performance material known for its exceptional durability and resistance to abrasion, impact, and chemicals. Its superior strength makes it ideal for demanding applications where reliability and stability are required. PE 1000 offers low friction and excellent sliding properties, making it suitable for conveyor systems, bearings, and wear strips…

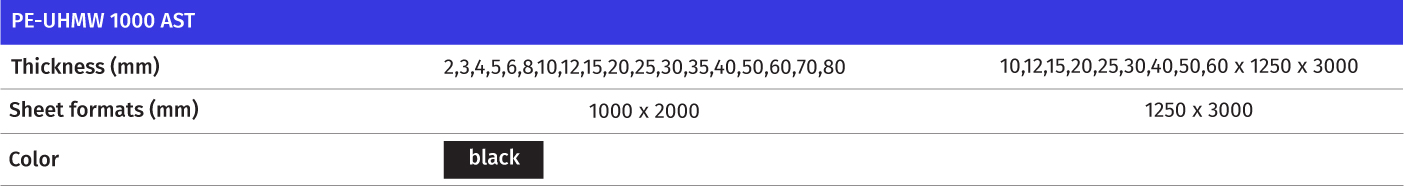

PE 1000 - PE UHMW AST (ANTISTATIC)

PE-UHMW 1000 in an antistatic version is a highly durable engineering plastic with exceptional wear and abrasion resistance compared to metals and other materials, thanks to its maximum molecular weight. The material is very slippery and has outstanding dimensional stability, even at extremely low temperatures (down to -200°C). Another key advantage of PE-UHMW 1000 is its very low moisture absorption, excellent electrical insulation properties, and, importantly, its non-toxicity, making it suitable for use in the food industry.

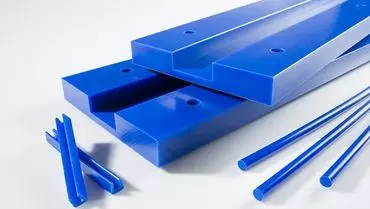

LubX®CV

A new type of high-molecular-weight polyethylene (PE) from the manufacturer Röchling, featuring special lubricating additives that significantly enhance its slip resistance and wear durability compared to standard PE materials. These additives improve the material’s friction properties, making it ideal for demanding applications where both low friction and high wear resistance are essential. The material is available in a vibrant blue color and is produced in the form of rods and sheets. It is specifically designed for direct contact with food, ensuring it meets the necessary safety standards for use in food processing and handling environments. Size and availability on request.